Maintaining 5S self-discipline

Posted by PASI JULKUNEN

4S Standardize, Shitsuke. "Standardize 1S-2S-3S"

Pentti Enlund4.12.2025

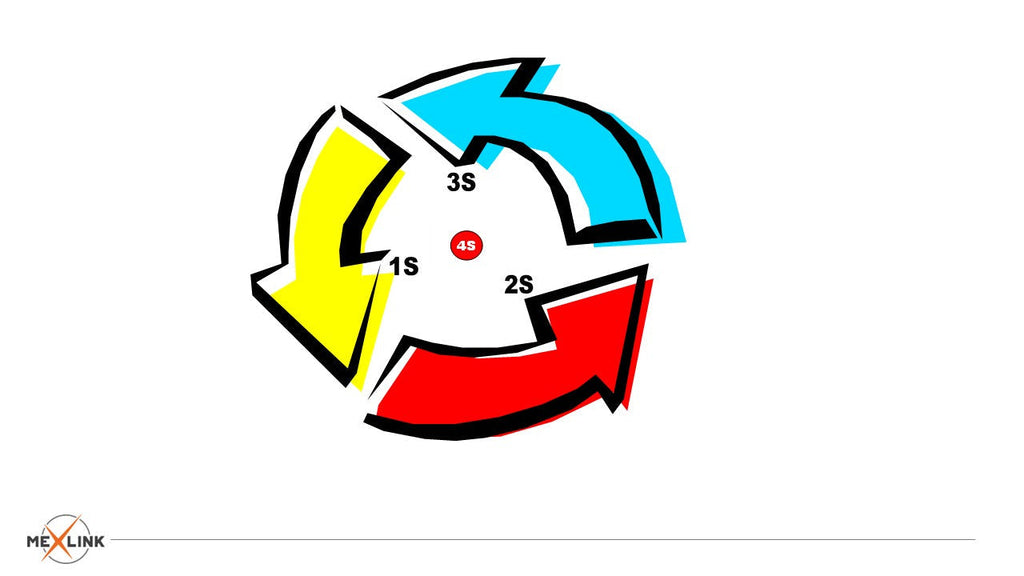

In my previous blog I explained what 1S-3S mean in practice. They were treated as separate steps so that the elements they represent can be implemented in the target process. Next, they need to be integrated into everyday work to be performed routinely, this is called the 4S phase, Figure 1.

Figure 1. 1S,2S,3S for routine everyday work

Properly performed standardization avoids, for example, the following problems:

• The previous state of disorganization returns, even after a company-wide 5S campaign has been carried out

• At the end of the day, a pile of unnecessary items left over from making production targets is scattered around the work area and machines

• Tool storage areas are disorganized and need to be put back in order at the end of the day

• During machining, cutting chips fall to the floor and need to be cleaned up.

• Even though 3S has been implemented in the office, it doesn't take long for an office worker to start collecting items that are no longer needed for their work.

Benefits of the 4S phase

• Helps control tools and machines

• Keeps the work area clean and functional

• Anyone can check the cleanliness level and situation of the work area

• It allows you to stay in the 4S phase so you don't have to go back to the previous three Ss

4S, Standardization Implementation

1. Division of 3S responsibilities

When maintaining a 3S environment, everyone needs to know exactly what they are responsible for, when, where and how to perform the tasks. If responsibilities are not clearly divided within their own work area, 3S activities will not have much meaning. Three separate tools are usually used to define responsibilities:

1.1 5S Map for assessing a single cell, production line or entire department.

Figure 2. Organization of workstation activities according to workflow

More on the topic on my blog https://www.mexlink.fi/blogs/news/gemban-talo- ja-sen-merkitys-standardoinnille (Figure 2).

Cleaning campaign planning, scheduling and responsibilities

First, the maintenance and cleaning targets are defined. Figure 3. They are grouped into three categories:

• Inventory products (raw materials, subcontracted parts, self-made parts, components to be installed, semi-finished and finished products)

• Equipment (machines, welding tools, cutting tools, measuring instruments, jigs, workbenches, drawers, chairs)

• Spaces (floors, work areas, walkways, walls, columns, ceilings, windows, shelves, rooms and lights)

After this, the task performers are decided. The tasks belong to everyone who works in the area. The factory is divided into maintenance areas, which are then assigned to people. This is called the 5S responsibility area map (Figure 3).

Figure 3. 5S Responsibility Area Map

Cleaning methods must also be defined and the tools to perform the cleaning.

1.2 5S work procedure for daily cleaning at the workplace.

This is called a visual 5-minute clean. This details what needs to be cleaned, how it will be done at a specific workstation, on what days and at what times of the day, and who is responsible. The schedule should be posted on the workstation notice board. Cleaning should not take too long, around 5-10 minutes is the maximum (Figure 4.)

Figure 4 Daily cleaning routine

1.3 The 5S work cycle diagram is a tool

The purpose is to show in which order each step in the 1S-5S phases is to be performed and how often in each area. Figure 5 shows the tasks for the first three pillars. Those performing the tasks can use this table as a 5S checklist.

Figure 5 5S Workflow Form

2. Incorporate 3S responsibilities into routine work tasks

If 3S operations are only carried out when deviations from the standard are detected, the situation has been misunderstood. Maintenance must become a natural part of everyone's regular work routine. In other words, 5S, focused on maintaining 3S conditions, is part of the normal work flow. Sometimes this is called 5S line integration. Visual 5S and 5-minute 5S are tools that make it easier to integrate 5S maintenance work into everyday work routines.

Visual 5S

The goal is to make the 5S approach visually appealing, meaning that anyone can see at a glance, without effort, whether everything at the workplace is as planned or how the work should be done. Below are examples of visual 5S activities.

Figure 6. Practical examples of visual 5S implementation

The examples illustrate: a work step; avoid using doors in cabinets by making the cabinet transparent; show the tools involved in the work step; a clamping tool that automatically returns to its place.

5-minute 5S

The 5-minute visual tidying technique, Figure 4, was discussed earlier, covering 1S-3S. The 5-minute visual 5S is similar, but covers all five points. When applying the visual 5S approach, the working environment of the cell acts as a trigger for identifying deviations (e.g., overproduction, disorder, soiling). Figure 7 The five minutes is only a guideline for the duration of the operation; the correct time can be whatever is appropriate for completing the tasks.

Figure 7. Five-minute 5S

(1) The procedure in Figure 10 is carried out in those work areas where the 5S method is in effect. (2) The following scoring is used in the inspection procedure:

• (5 points) if the working area in the section under consideration fully complies with the standard

• (3 points) if the working area in the section under consideration partially complies with the standard

• (1 point) if the working area in the section in question does not comply with the standard even partially

(3) This table must be completed before starting the 5S program in order to compare the change to the original situation (4) And again when the 5S program is running (5) The results of each survey must be displayed on the bulletin board of the workstation being surveyed

The visual indicator of inventory level is part of the visual five-minute 5S activity (Figure 8).

Green = Inventory level is acceptable

Yellow = Stock level is too low

Red= Inventory is below minimum level

Figure 8. Visual inventory level indicator

3. Check the 3S maintenance level

Once 1S-3S have been incorporated into the daily work routine, we next assess how well all three points are maintained. Here we use the Tidiness and Orderliness metric. As an example, here is a checklist we use in one cell. Figure 9 .

Figure 9. Order meter

5S process evaluation methods

Process evaluation methods used (according to Masaaki Imai) include, for example, self-evaluation where a cell employee evaluates the level of cleanliness and order, 5S expert, supervisor evaluation, a combination of the previous three. Competition between cells helps to achieve results. The factory manager sets up a competition between cells and the production management evaluates the 5S results of the best and weakest cells. The best cell receives attention, for example, in the form of a monetary reward and the weakest cell receives a brush and dustpan, as well as an encouragement to do better next time.

Factory and manufacturing management must conduct regular assessments to monitor progress. Often, disorder returns to the cell when focus is lost, so company management must build a monitoring system - for example, a sequence meter (Figure 9) - to monitor results and progress to ensure the continuation of the 5S system.

5S documentation system

An example of a system implemented as a content, which includes a cleanliness ranking index and its goals, pictures of team members, best practices identified, audit targets, auditees, task plan, visual 5min cleanup and progress of red tag tasks/tasks. The board is located on a computer where it is maintained, but selected parts of it are transferred to the cell bulletin board.

Figure 10. Example of a 5S documentation system

5S Maintain self-discipline, Seiketsu

I have gone through the techniques used in my previous article and above 1S-4S and have come to standardize good habits and techniques. Next, we need to consider how these achievements can be maintained through self-discipline. Self-discipline is related to good habits and the will to maintain them.

Figure 11. Combination of good habits

Good habits are a combination of knowledge, skill and will. Knowledge is gained through research and study and answers the questions What and Why. Skill is gained through doing and answers the question How. Will is developed by improving motivation and expresses Desire.

“We are what we do. Excellence is not an action, but a habit,” said the famous philosopher Aristotle.

I discussed this issue in my article in this blog series, https://www.mexlink.fi/en/blogs/news/kaizenin-syvin-olemus-on-ihmisyyden-kunnioittamisessa

The thinking model I present in the article is the starting point for why an individual wants to do something for their well-being and experience the joy of creation and respect for humanity. It is about the deepest essence and goals of Kaizen.

The question to be considered is whether the benefits to the individual are greater when

The question to consider is whether the benefits to the individual are greater when self-discipline is implemented than when it is not implemented. The following thoughts may arise as a result of this reflection: the work cell becomes more pleasant to work in, the work satisfies its creator more, communication with colleagues becomes easier, the work becomes more efficient and produces better quality, etc. Maintaining self-discipline cannot be measured in the same way as was done for the things in sections 1S-4S. But the company can create conditions that help maintain discipline. These are described in the book 5S for Operators, 5 pillars of the visual workplace:

• Awareness . Employees need to internalize what the five pillars entail and how important it is to maintain them.

• Time. People who apply 5S must have enough time at work to perform 5S activities.

• Structure. There must be instructions on how and when to perform 5S activities

• Support. Those performing must receive support, resources, and good leadership from company management in the form of recognition for their actions.

• Awards and recognitions . Good performance is rewarded.

• Satisfaction and joy of accomplishment . 5S implementation must be fun and satisfying for the person doing it and the company for whom it is being done. Satisfaction and joy of accomplishment are transferred from one person to another, enabling 5S to spread throughout the company.

Tools and techniques for maintaining self-discipline

5S slogans are used to communicate each of the five pillars in a company. The slogans are developed by employees. For example: All things in their place and a place for all things. We are what we do, excellence is not an action but a habit. Let us reinforce the use of 5S in our company. If nothing is done, nothing will change.

5S Posters display 5S slogans or descriptions of 5S activities. The purpose is to communicate the importance of all five pillars or to present the results of 5S activities to everyone. Images 12 (Volvo Arvika Plant)

Figure 12. Example of an internal communiqué

Photos and stories of 5S projects before and after the project (picture 13)

Figure 13. Example of before and after 5S implementation

5S newsletters are internal news about the five pillars. They contain factory reports on the 5S situation in the factory and activities around the topic area.

The 5S initiative system is a system intended for implementing employee improvement suggestions. In it, the initiator fills out the initiative card shown in Figure 14 and records it in the company's tracking system. The tracking system can be the company's initiative system described earlier or, for example, part of the 5S documentation system. https://www.mexlink.fi/blogs/news/kaizen-toiminan-jako-eri-segmentteihen

Figure 14. Example of an initiative card

The 5S pocket book contains definitions and descriptions of the five pillars, it must fit into the employee's pocket. Attached is an example of a pocket book written by me and my colleague Jorma Hakala for Tamrock and the then MET (Finnish Confederation of Metal Industries), now the Finnish Technology Industry. Figure 115 Floor-level workers, supervisors and production management use the pocket book as a reference list for essential 5S matters.

Figure 15. Implemented pocketbook

5S factory tours are used as an example for departments that have not yet started to apply the 5S method. This is an effective method to promote company-wide 5S implementation.

5S month is the 1-3 months of the year when several related activities take place, such as 5S seminars, field visits to other companies, and various competitions can be organized in the company to promote the implementation of 5S.

In my blog series, I have discussed 5S activities in terms of cleanliness and order, this is the basis for all production activities. But it is just the beginning of the larger idea that modern production, in order to function, includes various processes that must be able to be functionally connected. All of these processes are connected by 5S activities. I have written about the Gemba House where customer value is created and on which 5S activities are based, in addition, I have told how 5S works as a cornerstone of Lean production and how KAIZEN and 5S are related to each other. Next, I will write about TPM activities (Total Productive Maintenance), on which 5S activities are also based, and what kind of 5S elements support Total Productive Maintenance.

Pentti Enlund

MexLink Oy

English

English Finnish

Finnish Swedish

Swedish German

German