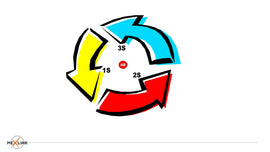

Once 1S–3S (sort, set in order, shine) have been implemented, the work is only halfway done. The next crucial step is 4S – standardize – where cleanliness and order are transformed from random campaigns into visible, repeatable, and measurable routines. The blog discusses how 3S responsibilities can be integrated into everyday work using 5S maps, area of responsibility maps, 5-minute tidying routines, and visual indicators to prevent old disorder from returning.

Towards the end of the article, we move on to the 5th S – maintaining self-discipline (Shitsuke) – and look at how good habits can be maintained in everyday life. Knowledge, skill, and willpower come together when a company supports 5S activities with structure, time, management support, and rewards. Through examples, pictures, and practical tools, the blog shows how 5S becomes a permanent part of the production culture and lays the foundation for the next step: TPM (Total Productive Maintenance).

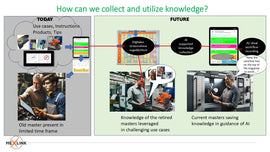

In November, we will demonstrate what holistic artificial intelligence is capable of. The Mexwiser AI assistant consists of two cores: the maintenance technician's thought process and a background knowledge map. These ensure that different maintenance technicians can quickly get up to speed with maintenance work management. Active artificial intelligence ensures that maintenance work is documented and that dynamic skill levels in different maintenance situations are recorded for use in future maintenance work. Mexwiser is an experience-based artificial intelligence assistant. It consists of several AI models and software components, as well as a structure designed specifically for this purpose.

Mexwiser® – The Missing Thinking Layer in Maintenance

Mexwiser® is not just another analytics dashboard – it’s the critical thinking layer that turns detection into consistent, repeatable action. Instead of overwhelming technicians with terabytes of data and vague alerts, Mexwiser drives structured root cause analysis, resolves entire fault chains, and embeds sustainable, standardized repair processes.

At its core are the Master Workflow and the Competence Map:

Master Workflow distills over 30 years of global maintenance experience into precise, step-by-step guidance that reduces MTTR, ensures quality, and boosts the confidence of both new and seasoned technicians.

Competence Map links every task to skills and decision-making logic, identifies gaps, and feeds new insights directly back into daily operations.

Mexwiser® ensures your maintenance runs faster, more consistently, and with preserved expertise – now and in the future.

In our Kaizen article series, practical experiences compiled by our expert Pentti Enlund: 5S is not a byproduct of cleanliness, but an effective and practically tested method for developing production. In the blog, I will tell you how we have applied 5S for decades in Finnish industry – and how it has helped achieve significant improvements in quality, productivity and working atmosphere. Especially in the manufacture of niche products and long life cycles, 5S brings predictability, continuity and a competitive advantage.

In manufacturing industries in Germany, Sweden, Finland and the Netherlands, up to a quarter of the workforce will retire in the coming years. At the same time, the number of training courses does not match the number of workers leaving, and the attractiveness of the sectors among young people needs to be significantly improved.

MexLink's Mexwiser artificial intelligence solution meets this challenge by capturing the valuable tacit knowledge of retiring employees, accelerating onboarding and ensuring the industry's competitiveness in the future.

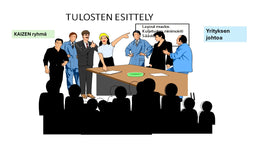

The Kaizen method is based on continuous improvement at all levels of the organization. Strategic changes by management, quality circles by teams and individual initiatives together create a systematic development culture. The initiative system ensures that improvement ideas are transformed into concrete actions that achieve efficiency, savings and a better working environment.

This presentation is a continuation of the previou

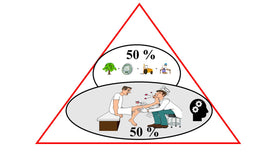

ZEN and the art of understanding

When a person is

English

English Finnish

Finnish Swedish

Swedish German

German