Kaizen steps (5/10 steps)

Posted by PASI JULKUNEN

ZEN and the art of understanding

When a person is told how work should be changed, it is surprisingly difficult to accept it, because he remembers only 10% of what was told and 15% of what he saw, and 20% of what he saw and what was told together. This mode of operation is typical in boss-dominated organizations. Tell me and I'll forget.

When a person is taught interactively , he remembers 40% of his conversations with colleagues, which is typical in organizations dominated by managers. Teach me and I will learn.

When a person is included as part of the development work, he understands what it is about through his experience and it creates enthusiasm to develop his own work. A person remembers 80% of what he experiences. This is typical in coach-dominated organizations. Take me along and I'll understand. Figure 1.

Figure 1. The steps of learning

The most effective form of learning is teaching , where a person learns 90% of what he teaches others. The understanding of Kaizen group management and competence grows from this idea, group members eventually become its leaders through increased understanding.

The 10-step method discussed next is intended as a guideline for the company's management, the leader of the Kaizen group and the group members for successful development work. It follows the development work of the Japanese masters following the framework created by the American Deming and is a standardized format. Those who use it state that the better the production process is under control and the more precisely its costs are known, the better this method can be used to identify and eliminate the waste still occurring in the process. On the other hand, it is a great tool to develop different processes and implement many methods that are part of Lean production. This paper follows the method used in the industrial process.

How then in practice, the 10-step method

Before the start of the process, it must be ensured that the activity has the commitment of the company's top management , without which it is not worth starting goal-oriented Kaizen activities. Commitment means establishing a steering group, development work during working hours, freeing up the necessary resources for group work, maintaining a good working atmosphere, supporting the group by showing genuine interest and enthusiasm for its work. Management participation!

1. Start with the topics Quality, Delivery, Costs (Q,D,C)

The purpose of Kaizen activity is to check, change or correct the process from the existing situation to a better one, by removing everything unnecessary from the point of view of the process and by eliminating existing problems. Work is started from within the company, i.e. on topics raised by internal customers, by choosing a suitable topic from the Q, D, C areas. Examples of this include parts that require repair, performing a process step multiple times, or the need for overtime to meet normal production requirements. A Kaizen coordinator is appointed for the preliminary study, the direction and goals for the project are indicated. In addition, define the tasks that must be done before moving to the next phase, such as e.g. group leader, filling out the project monitoring cover sheet for phase 1, describing the current state, etc.

2. Choose a group around the topic

The ice hockey team needs reinforcement, there is a center shortage. The coach turns to the floorball team and hires a top center. What do you think the players on the team think when a newcomer appears in the booth, a great guy, but plays a different game when called upon?

The same applies to the selection of the Kaizen group, for which people must be selected from different expert groups who know the problem to be dealt with and want to get rid of it, in order to make their own work easier. The group includes employees working in production and support staff, if it is a production activity. The group has to write down their goals on the cover page, so the words become goals on which efforts are directed. In addition, we need to think about why we are here today, what are the goals of the company, the department and the group, why we want to use teamwork, the stages of creating a new culture, the elimination of resistance to change, the stages of increasing employee enthusiasm, what we need from the management team and a clear direction in which to proceed.

Imagine you are a hockey player, you are playing but you don't know how much the situation is in the game. How motivated are you to play if the score doesn't matter? We need a scoreboard to keep the sunnah correct. The board describes the group's goals in the current project and how they relate to the goals of the cell, department and factory.

Tasks before the next step, e.g. naming the group, group leader, meeting time, agenda and place of the first meeting, team building exercises, etc.

3.Identify and describe the existing situation, breaking it down into its smallest components

Good personal relationships help reduce the biggest form of waste in organizations, employees

not using talents and skills. This is the most effective tool available in terms of group motivation. People work more efficiently when they realize they can influence the way things go. Therefore, the ideas asked from people and the genuine interest shown towards them, raises the self-esteem of the presenter of the ideas. It is also the key to finding everything useless and unnecessary in the process.

It is generally recognized that plans cannot be effectively implemented unless they are fully understood

what it is about, in the existing situation. We often use the phrase in this context, Lock the existing situation. It means that all factors of the considered process are locked in time with the help of video analysis. With the help of this information , Standardityo lehti (SWS) is created. Materials flow analysis and Machine downtime analysis can also be useful for the group.

Pareto analysis is also used to map identified problems and find out their components. The process is broken down into its smallest components and then analyzed later. After that, every problem or form of waste that occurs in the process is identified.

What cannot be measured cannot be standardized, what cannot be standardized cannot be improved.

Tasks before the next meeting are e.g. continuous time analysis and how to do it, filling out the standard worksheet about the existing situation, material flow analysis, if required, recording the time study analysis, time study graphics, etc. The cover sheet is also filled in for phase 3.

A list of things to remember, such as brainstorming rules, repeating the seven forms of waste in an existing project, what gets measured gets done.

4. Set goals

Imagine reading a story with a great beginning but no end. A Kaizen team without goals is like a story without an end. No matter how good the beginning, everyone loses interest before long, without set goals. Setting goals is an important task for a group. It requires cooperation and consensus from the group. The goals must be challenging and yet realistic and achievable. The most important thing is to write them down. It is done by recording the goals in the Schedule template, where the target completion time of each process step is recorded. Each group member signs the goals as a sign of commitment and ownership. In addition, it is important to write down the description of the problem we are working on and the goals for improving the work. This clearly tells where the group is going and when it should be there. As an example of possible problems, an excessive number of corrections in the pieces being produced and the goal being flawless pieces. Too many downtimes in the process. The goal is to increase the efficiency of the process by 75% => 85%.

The name and goal of the topic to be discussed should be repeated at the beginning of each meeting, it is easier for the group to focus on the right topic. The next step in goal setting is to write down the exact goals on the Kaizen cover sheet, which is used to track the project's stages and results.

The group must complete the work within 2-4 months, otherwise the focus on the work will be lost.

5. Cause-effect analysis

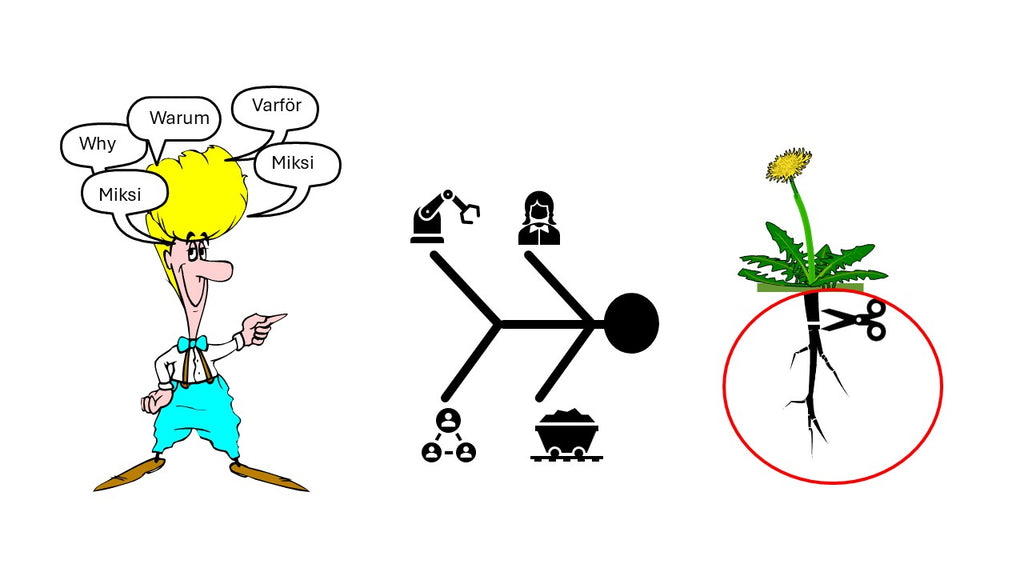

This is the ideation phase, when the root or basic causes of the problems are identified. The phase is very interesting, but requires a good leader so that the group focuses on identifying the causes and not the solutions. The use of a herringbone diagram (Ishikawa diagram, Cause-Effect diagram) helps in structuring information by showing the connections between cause and effect. After this, by asking why five times, we get to the root causes of the problem. 5W shows the connections between the cause and the root cause. Figure 2.

Figure 2. Searching for root causes

Root causes are the basic causes of the problem being addressed. Continuous operational improvement is the elimination of root causes.

At this stage, it is good to repeat the rules of the ideation process, which serves as a good introduction to this stage.

When the ideation phase is over, the group must look at the identified root causes. From these, the most important ones are selected for more detailed analysis. Too many may prolong the project too much, choose those that have the greatest impact on the set goals.

Before the next step, the problems and forms of waste that the group will eliminate must be identified. The seven forms of waste have to be gone through again.

The first five steps of the 10-step method are outlined above. I will go through the next five steps in a future article. This is because if everything were to be covered in the same article, this story would become too long to read at once.

Pentti Enlund

MexLink Oy

English

English Finnish

Finnish Swedish

Swedish German

German