How customer value help to achieve cost control?

Posted by PASI JULKUNEN

How customer value help to achieve cost control?

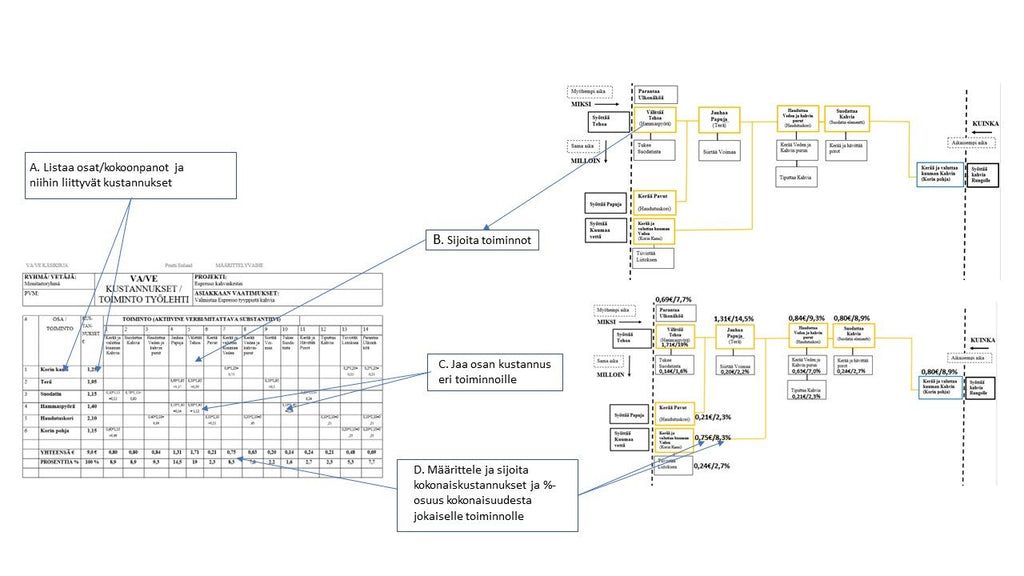

In this Target Costing treatment, we continue the story of the Espresso coffee machine, which is worth repeating from the previous article "Identifying opportunities based on FAST analysis". The starting point of Figure 1 is the matrix connecting the sub-assemblies of the functions and the product as a continuation from the previous article.

Figure 1. The Cost-Function relationship of the brewing basket and its FAST diagram

Shown above is a flowchart for evaluating a product's Cost-to-Function ratio/FAST chart (Figure 1). The diagram shows how to transfer the functions from the FAST diagram to the Cost - Activity worksheet (B), divide the costs of the parts into different functions (C) and place the cost of the functions (€) and the total cost (%) back into the same FAST diagram (D). In this way, we have created a FAST chart, where each function, its cost and the percentage share of the total cost are shown in the same picture.

Ideation phase and alternatives

The goal of the coming ideation phase is to create different solution options that meet the requirements set by the customer for the assembly, at the target cost price. Neither requirement can be compromised. The price of the current solution is €9 and the calculated target cost is €6.64 (-26% drop).

In the ideation phase, I listed the cost reduction ideas related to the brewing basket assembly in a table in my previous article. They include reducing the size of the brewing basket, eliminating the gear, reducing the size of the filter, reducing the size of the blade, reducing the size of the basket lid and reducing the size of the basket base (Figure 2).

Figure 2. Different solution options

The performed analysis shows that option A achieves the target cost and functionality goals. So is it happily chosen as a solution, because under normal circumstances this is how it would be done?

There is no choice, because it is about calculating customer value, where cost is one element, but as we will soon see, there are other elements that must be calculated and evaluated in order to calculate customer value. First come the selection criteria to find a solution.

Rules for forming selection criteria and their mutual importance

1.Identify the selection criteria

Examine the customer's requirements for the product, as well as the information developed during the function identification phase and identify the selection criteria against which the team evaluates each proposal. Typically used criteria are e.g. Performance, Reliability, Durability, Product aesthetics, Weight, Maintainability . Figure 3.

2.Classify the criteria

Define the relative importance of each criterion in relation to each other, describing it on a scale of 1-10. (10 represents absolute necessity). The purpose of the definition is not to arrange the criteria in order of importance, but to describe the importance of the criteria on a scale of 1-10. Therefore, it is possible to get the same score for several criteria (Figure 3).

Figure 3. Comparison and prioritization of solution proposals based on customer needs

3. Classify the developed alternative proposals; A, B, C, Current

Go through the options developed by the design, giving each a rating number from 1 to 5, indicating how well each proposal meets that criterion (5 being excellent). Remember that you are comparing proposals against each other (Figure 3).

4.Calculate the weighted sum for the criteria. (WE, Weighted Evaluation)

Multiply the proposal's classification number (1-5) by the criterion's relative importance number (1-10) and record the result. Do this for each criterion, and add up the weighted values of each proposal in each option column. The resulting amount is called the weighted amount. (Figure 3.)

We see that the highest weighted sum is for proposal B 144, then C 135, while the weighted sum of the current solution is only 95. These numbers must be interpreted in such a way that proposal B best fulfills the requirements of the presented criteria. The question can be asked, is proposal B the best option to implement?

In the same way as when calculating the costs, the answer was, it is not yet known because the costs have not been taken into account in the calculation.

Figure 4. Calculation of value ratio, i.e. customer value

The value ratio, i.e. customer value, is calculated by the weighted sum of the Activity / Unit cost. The higher the number, the better the solution. Then we see that the best customer value is option B 20.72 at a cost of €6.95 and then option C at 19.23 at a cost of €7.02 and A at 17.92 at a cost of 6.64 while the customer value of the current option is only 10.56 at a cost of 9 .00 €.

The planning team now has to consider the tricky question of whether to sacrifice customer value or cost. Solution A reached the target cost, but has a lower customer value than option B, which in turn has a higher cost than A. C's cost is high, but the customer value is between A and B.

Due to the recursive nature of the target costing concept, when planning costs out of the product, both maximum customer value and the cheapest solution can be achieved at the same time, but this requires in-depth analysis and several rounds of iteration.

The next steps of the VA/VE concept

The next step in the process is making a recommendation about the best option and presenting it to the management. This includes the following steps:

-

Current solution, new recommended solution and its pros and cons

-

Reduction of labor costs, reduction of material costs

-

Annual number of units to be produced, annual savings, payback period

-

Lifetime manufacturing volume, lifetime savings, first year savings, etc

-

The last stage is the implementation stage

It is worth keeping in mind that even the best idea in the world is worthless if it is not implemented. The action plan and scheduling for implementation are the most critical things that must be presented to the management.

Postscript

This article I wrote is the sixth in a series and all of them have been published on the Mexlink Oy website /Pearls. The story series tells how the VA/VE process progresses systematically and what it contains in its various stages. Due to the limited use of space, the broader analysis I wrote is not possible in this context.

The VA/VE process, together with the Target costing concept, forms a superior tool in cost management, and with this concept, the costs of any product can be managed when the customer has set cost, quality or functionality requirements for the product, which must not be deviated from at any point in the process.

The described techniques can also be used when working alone. However, the organization gets the full benefit, the highest possible ROI, when multi-skilled teams improve two things 1. Meet how the business is managed from the point of view of product, process and system development and 2. Customer satisfaction is improved.

Pentti Enlund

Mexlink Oy

English

English Finnish

Finnish Swedish

Swedish German

German