COST MANAGEMENT DURING THE LIFE CYCLE OF THE PRODUCT

Posted by PASI JULKUNEN

A phenomenon of the times is the increase in costs and the vulnerability of supply chains, which eat away at the profitability of companies. In addition, the use of digital technology brings new hidden costs if you do not know how to connect them to event chains throughout the entire life cycle. In addition, I predict that the green transition will also change the value/cost ratio in economic indicators.

Why does cost management focus on individual visible costs? Often, for example, economic cycles are quickly reacted with structural changes and layoffs. Sometimes this drastic measure can change structural competitiveness, but most often the cost savings sought by it lead to changes in the competitive landscape or profitability. Various elements can be found in the income statement, where the visible cost is personnel costs, which are considered the fastest to be cut. One of the reasons for the lack of long-term cost control is probably the many and deep roots of a simple phenomenon in organizational culture, supply chains and product characteristics.

It often happens that short-term work is cut and the work of the lost resources is hidden in the form of some degree of self-service as a cross for the remaining personnel. The deterioration of productivity happens over a long period of time and without being noticed, because the capacity needed to survive in the short term cannot be compromised. The capacity has decreased as a whole and the existing capacity of an individual person is burdened with new tasks. The depth of concentration loosens and the scope increases (Figure 1).

Figure 1. Extreme choices of used capacity

However, different unproductiveness is often hidden in large quantities in products and the way they are produced. In the income statement, these are hidden behind the numbers and above all in the connections of different cost/value elements, which makes it difficult for the management to make real cost savings that support productivity. In products, which is typically the biggest factor due to their scalability, this unproductivity hiddenness is the most challenging.

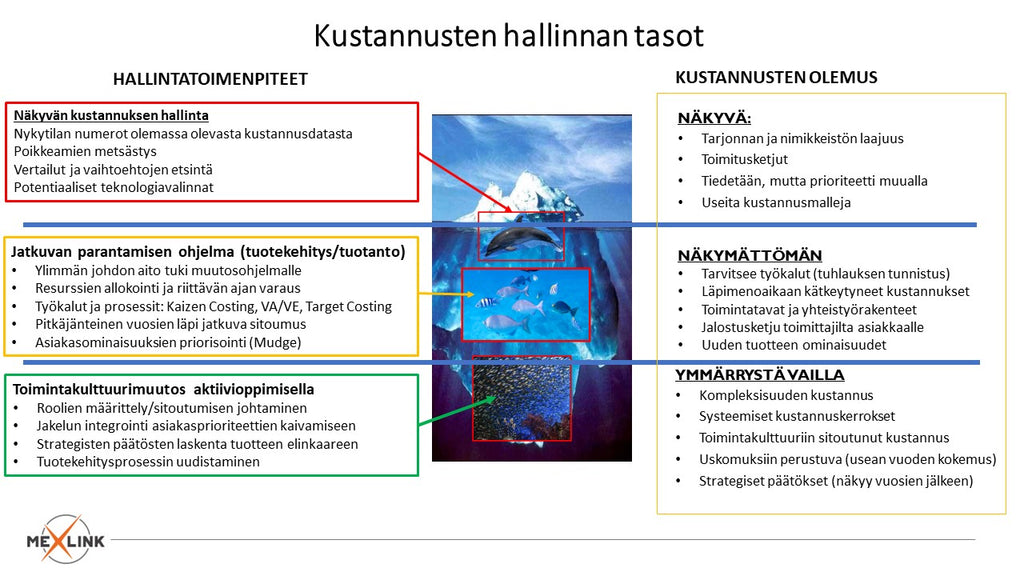

What are the means to get to the root causes and the real development of productivity? Costs can be identified in three levels (Figure 2):

1) A visible cost that you don't always have time to focus on (requires work)

2) An invisible cost that needs its own tools

3) Unconscious cost, which is hidden in the operating culture formed over the years

Figure 2. Levels of cost control

MexLink's cost management resources and scientific research network have been applying Toyota's original tools to small series industrial operations. The concepts and the value and costs of current products and functions as well as product development have been tested in numerous companies. We were lucky to get coaching directly from one of the hardest cores of cost control – the Japanese automotive industry. It is substantive excellence that we also want to instill in companies, as the whole concept is based on the transfer of tested methods of operation and tools to the company. The know-how was perfected through practice in the Finnish manufacturing engineering industry and also with logistics operators. The new area we added to the concept was spare parts and maintenance-oriented service. Naturally, the company has to invest its own resources in this transfer of know-how, because "the water carried to the well usually does not stay there".

A scientific cost study, in which numerous Finnish companies have participated, has revealed the setting of the goal as one of the key bottlenecks. Mistakes in setting realistic goals and on the other hand in disciplined implementation lead to a typical situation where the value of the product's features exceeds the customer's willingness to pay. You can easily create a "flagship" with more features than the customer needs, naturally limiting customers and volume with its high price.

A new challenge has arisen is the green transition and digitization uttered in a deep chest voice of complete ignorance. The green transition changes priorities, and digitization, when implemented incorrectly, generates hidden costs in addition to the benefits it brings, especially during its life cycle. Commitments to costs, invisible at the beginning through choices, pop up after a few years, taxing the profit.

How do you get to grips with this wider phenomenon? The development path of an individual company is only sufficient for the first steps. One way is to form alliances more broadly. We have built content for this with the EU/ITEA4 project consortium and achieved a challenging expedition into the depth of cost management while simultaneously tackling CO2 minimization.

Our research journey begins with goal setting and ensuring its correctness by clearing customer needs from technical solutions, which is part of the target costing process. It takes with it the product structure architecture with new interfaces, forming a map for a large entity. As sugar, there are proven tools and thinking models at the bottom with which we can get to the bottom layers of the cost iceberg (Figure 3).

The challenge of an ecosystem-like operating model comes from the area of the green transition and the management of the IPR of the supply chain, as well as the seamless CO2 chain verification required by the customer. The aim is to respond to these with technological means, i.e. Blockchain in new clothes outside the banking world and analytics and simulation tools made agile by artificial intelligence.

Profitability management becomes a kind of pareto optimization task in a large supply network. The redeemable value potential can also be enormous. The operators of a process industry are planning to invest a total of 750 billion USD in sustainable development, where Blockchain has been mentioned as one of the potential technologies. What is revealed from other sectors?

Figure 3. Limitless/ITEA 4 Finnish project

The reference framework for Limitless/ITEA 4 EU funding has been passed through two demanding gates and our project is included, which has so far involved one Business Finland (BF) locomotive company and TAMK and VTT. We still need companies to join us, such as I am interested in the project, modeling and profitability and CO2 minimization .

A completely new opportunity requires acceleration with the investment of public money. EU concepts are relatively basic in Finland, and even civil servants are afraid of mistakes. This makes getting funding challenging, because it is not enough to win the demanding EU struggle. We have to take another win on the domestic financial front, which requires solid corporate participation and will power. Alternative paths of advancement are either a research concept, where companies participate in the guidance and invest their resources in the transfer of know-how with their own contribution, or a Co-innovation project, where some companies have their own parallel projects. The schedule is the end of August 2022.

The advantage of a wider front is the acceleration of market entry, because the new emerging potential is huge. There, we can influence the know-how more broadly, and again, in company-specific projects, we can help solve profitability problems in an individual company and its supply chain.

MexLink operates as a producer of deep content and is able to orchestrate development in a wider ecosystem with the power of excellence and its extensive network of expertise refined over the years. We have proven world-class tools and the ability to take them to the development of companies' offerings.

9 May 2022/ Pasi Julkunen/MexLink Oy

English

English Finnish

Finnish Swedish

Swedish German

German