Identifying opportunities based on the results of the FAST analysis (Pentti Enlund)

Posted by PASI JULKUNEN

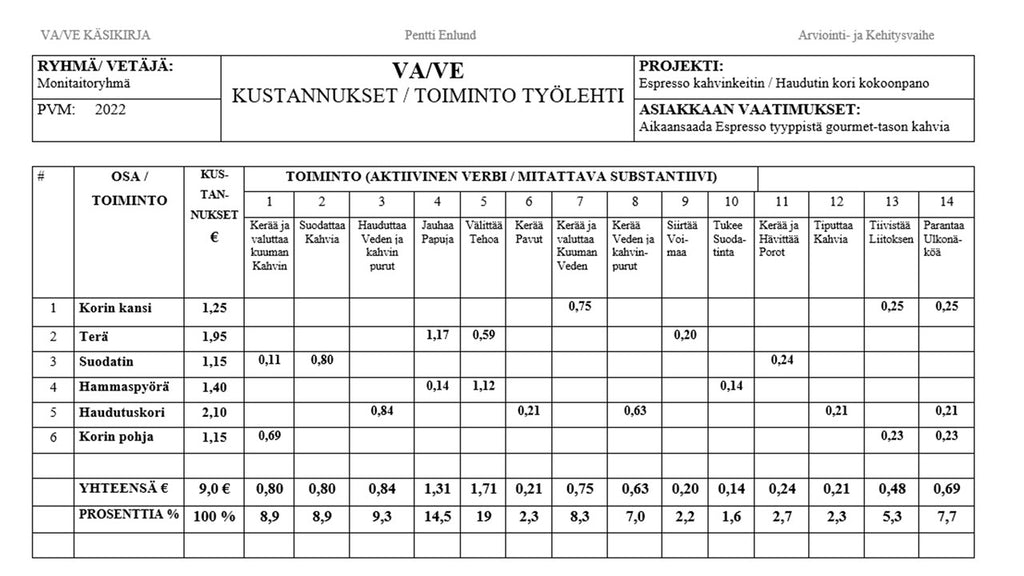

In this article, I aim to show how creative thinking can be used to produce alternative possibilities to achieve the desired functions . The design team identifies improvement opportunities and goes through them in a brainstorming session. As an example (Figure 1), I use the most central part of the Espresso coffee machine, i.e. the coffee brewing basket assembly. The activities for this cost/activity worksheet were collected from the FAST analysis. The task of this component is to grind the coffee beans into particles, evenly distribute the incoming hot water over the ground coffee powder, brew the coffee, filter the coffee, deliver Espresso gourmet level coffee to the next stage of the process, and collect the coffee grounds for disposal. The taste and aroma of the coffee is achieved with this subassembly of the machine, so the main customer requirements are directed to it.

Improvement opportunities for the construction or process are identified by determining the dependencies between costs and functions. This process is very important to keep the team's attention on the areas where the improvement opportunities are greatest.

Figure 1. Connecting costs and activities

It is a union of cost and function, where these two things are connected together. I refer to the attached picture in the following text.

The first thing is to make sure that the costs of the assembly's parts and assemblies, as well as the factors related to them, are recorded on the left side of the worksheet, in the Parts and Costs columns.

Next, we move all identified activities from the FAST diagram to the top of the page, in the Activity columns. Each function can be listed only once.

The cost of the component should be allocated to the functions in which it participates. In several points in our example, a part participates in the performance of several functions. In the case of the example, the basket cover (€1.25) , whose function is Collect and drain Hot water (€0.75), takes part in the execution of the Seal Joint (€0.25) and Improve Appearance (€0.25) functions. So we see that the function of the deck is not only to act as a water collector and drainer, but also to participate in the performance of two other functions. Some functions can also be completely free of costs.

When we look at the activities identified by the FAST diagram, we notice that the cost of a certain activity consists of the combined effect of several components. For example, the function Grind Beans (€1.31) consists of the costs of the Blade (€1.17) and the Gear (€0.14) , making up 14.5% of the total cost of the product.

In summary, the cost distribution can be seen, for example, as follows;

- The critical path has costs of €5.62 / 62.4%

- Costs of supporting activities €1.90 / 21.1%

- The cost of the basic function €0.80 / 8.9%

- All-time impressive cost €0.69 /7.7%

From my previous articles, we remember that the basic function is the reason why the customer buys the product. It is often surprising to note that the cost of the basic function is well below 10% of the total cost of the product.

The total costs of each function are summed up in their own Total column. In the percentage column, the percentage share of each activity in the total costs is calculated. At this stage, the group should identify 2–4 functions that are worth investigating in more detail.

Here, you should pay attention especially to critical functions . If most of the costs are here, then the current construction is relatively cost-effective. In such a case, we focus on the basic function (s) and develop a new concept.

Next, we will review the supporting functions . If a large amount of costs are allocated somewhere other than critical functions, it is likely that cost savings can be achieved without changing the basic concept. When making a change, you should keep the customer's requirements in mind, you must not compromise on them. At this point, it is worth looking at those functions that do not add value to the product and belong to non-supporting functions. In addition, examining expensive activities sometimes brings opportunities to implement them more cheaply. Below, Figure 2, are ways of reducing costs for different parts of the assembly achieved by ideation methods.

The action is defined by an Active Verb and a Measurable Noun . Figure 2 shows the Verb/Noun list of the components of the assembly being processed. For a measurable noun, the question, How much? For example, the function of the component Gear is Transmit Power. Regarding power, we can ask the question How much power? The answer is 180W. Looking at the other parts of the coffee maker (Power input), we noticed that the power can be reduced and it also affects our brewing basket configuration. 180 W is reduced to 130 W, so the gear wheel can be replaced with a drive shaft, which is clearly a cheaper solution.

Listed below are some general guidelines for reducing costs.

- To reduce the number of parts

- To simplify assembly

- Using standard parts

- Avoiding parts that will soon be obsolete

- Avoid over-designing the product for what the customer wants

A cross-organizational group is necessary because solutions of this type must be guided by the customer's will and financial guidance.

The cost analysis finds out which product components are the target of cost reduction measures and which subcomponents are assigned individual cost targets. For the coffee maker, this means deciding which components to allocate measures to, e.g. heating element, control panel, brewing basket assembly, etc. and what is the cost target for them. The analysis also defines the mutual interaction of the components (see power input vs. brewer basket configuration above). Cost-cutting measures taken in one component often increase costs in another component, but also reduce them, as in our example.

Cost analysis includes five main activities:

- Product component listing

- Allocation of costs to components

- Prioritizing the customer's requirements for the product

- Relating customer requirements to product components

- Determining the mutual importance of product components

The five points mentioned above are the initial impetus for the process of achieving the target cost of the product. In this process, when done correctly, the customer requirements for the product (the voice of the customer) permeate the entire design process, producing the functionality the customer wants, at a price they are willing to pay.

In my next article, I will discuss creativity and the suggestions for improvement brought about by it. In addition, the most significant part of the entire VA/VE process, i.e. the calculation of customer value.

31.3.2022/ Pentti Enlund - Mexlink Oy

English

English Finnish

Finnish Swedish

Swedish German

German

d-change.net On

Wow, this piece of writing is fastidious, my younger sister is analyzing these things, therefore

I am going to let know her.

D Change On

I do not even know how I ended up right here, but I assumed this post was good.

I don’t recognise who you might be however certainly you are going to a

famous blogger if you happen to are not already. Cheers!

d-change.net On

You could definitely see your expertise in the article you write.

The world hopes for more passionate writers such as you who are not afraid to say how they believe.

All the time go after your heart.

d-change.net On

Link exchange is nothing else except it is only placing the other person’s webpage link on your page at

appropriate place and other person will also

do same in favor of you.

https://d-change.net On

Hey there! Do you use Twitter? I’d like to follow you if that would be

okay. I’m definitely enjoying your blog and look forward to

new updates.