Function Analysis System Technique, FAST - Part 2 - author Pentti Enlund

Posted by PASI JULKUNEN

Function Analysis System Technique, FAST - Part 2

Functional analysis of a product or process, Part 2

In my previous story, I stopped at identifying functions. Here are some rules to define product functionality.

-

Use only two words, a verb and a noun , this forces clarity and breaks down the task into small, manageable parts

-

Use active verbs and measurable nouns whenever possible. Passive verbs limit creativity. The measurable noun enables costs to be determined precisely in the activity under consideration. By using a noun to be measured, questions are made possible in the next step, e.g., How much load? How much power? How much volume?

-

Avoid the verbs Get, Equip, Give and their synonyms when describing usability functions. They are mainly used to describe aesthetic functions.

-

Make sure you identify functions, not typical features or traits

-

Don't be too specific. Such descriptions tend to draw attention to the existing method and limit creativity.

Classification of functions

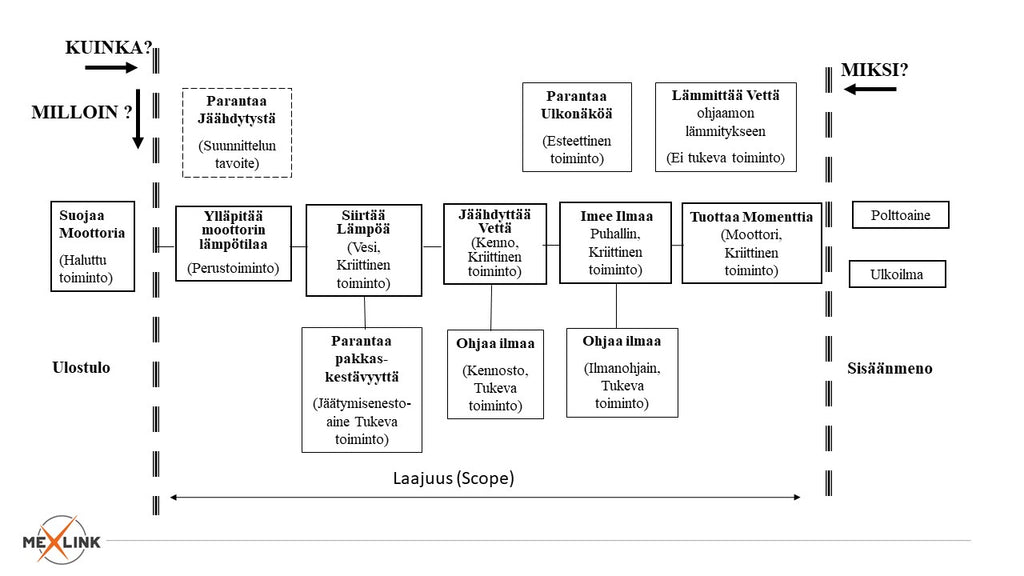

The functional diagram of the engine cooling system is depicted below, Figure 1.

Figure 1. FAST function diagram for cooling system analysis

A basic function is a job or function that a product or process is designed to do. It is the reason why the customer bought the product or the designer designed it. The basic function is usually easy to define, for example for the engine cooling system of a work machine it is Maintain the engine temperature . The basic function is tested by asking: If the function were removed, would the product still work perfectly? The answer is no, because removing a basic function makes the product worthless.

Critical function

Critical functions are the design engineer's choices to provide a basic function or functions. In the engine cooling system of the work machine, they are, Produces Torque (engine), Sucks Air (fan), Cools Water (cell), Transfers Heat (water).

Supportive function

Supporting functions are those that make critical functions work better, faster, longer, etc. In the case of the cooling system, they are, Directs Air (air guide), Directs Air (radiator cell), Improves Frost Resistance (Antifreeze).

Not a supportive function

They are any other functions, inside the view object, that have no effect on the basic functions. For example, aesthetic functions are often like this, unless the basic function is aesthetic in nature, as is the case, for example, with perfume or machine topcoat.

In the case of the machine's engine cooling system, one function is to Heat Water , but it has nothing to do with the basic function. However, the customer is willing to pay for it because they want it to happen, due to the fact that hot water can be used to heat the cab. However, if compared to the basic function, the function is not supportive.

In summary, the functions of an entire system can be accurately and clearly understood by identifying the hierarchical relationship between basic, critical and supporting functions. Each basic activity can have a subgroup of critical activities and each critical activity can have supporting activities that enable them to happen better, faster, longer, etc. Classifying and understanding the interrelationships of the system's activities is the core of the entire Functional Analysis and Cost Planning (VE).

Activity mapping process

The activity mapping technique, FAST, graphically shows that a product or process consists of interconnected activities (Figure 1). This technique can be used to test the robustness of functions and show missing or overlapping functions. The technique also helps the team establish the relationship between costs and activities, and helps select the subject areas that hold the greatest potential for cost savings.

Boundary lines and the scope of the task (Scope)

The long vertical lines in the activity diagram define the boundaries and scope of the work to be handled. All identified functions must fit between these lines. In an activity diagram, long vertical lines define the boundaries and scope of the work to be performed. All identified functions must fit between these lines. The right vertical line is positioned between the given inputs and the desired function. Functions answer the question, 'Why do we perform basic functions?

The left vertical line is positioned between the basic function being processed and the higher-level function.

Chart creation

It starts on the left side of the right vertical line, where the basic function(s) come. Next, the critical functions are placed on the same line, asking two significant questions, HOW this has been accomplished and WHY this function is performed. The activities placed horizontally must also meet the time sequence requirement , ie the activities are placed on the critical path in relative time order starting from the left end of the critical path. Activities that do not have a time sequence are placed below or sometimes above the critical path. These are activities that occur at the same time, or all the time, and are called concurrent support activities. Such functions include supporting functions (Controls Air), aesthetic functions (Improves Appearance = Engine Color) and unwanted functions (Heats Water).

The critical path

A critical path is a series of critical activities that run horizontally from input to output. The path is complete when the HOW and WHY questions have been tested for each critical function and when the path only has functions that satisfactorily answer both questions. This is what I call justification both ways.

Summary

An activity diagram shows activities that occur simultaneously and depend on each other. During the ideation phase, alternative methods of performing, eliminating and combining functions are developed.

A functional diagram represents an individual's or group's understanding and logic of the structure or process under consideration. If the same process is described in another group, the end result will probably be different, of course, in this case too, the general construction principles of diagram construction must be followed. This is because there is not just one right answer. The purpose of the action diagram is to deepen the understanding of the matter under discussion. As long as it serves the group's purpose, there is no right or wrong chart. This is also an opportunity for design engineers to show their creativity.

If a machine had a soul, it would be here. It is an invisible influence on which everything is built and whose existence only a few people know about. However, every product has it, you just have to dig it out.

In the next article, I will discuss how, based on the above, to identify opportunities to find improvement targets for the subject under consideration.

Pentti Enlund

Mexlink Oy

English

English Finnish

Finnish Swedish

Swedish German

German