STRATEGIC COST MANAGEMENT PROCESS (Strategic Cost Management Process - Part 1 by Pentti Enlud- to be continued)

Posted by PASI JULKUNEN

STRATEGIC COST MANAGEMENT PROCESS (Strategic Cost Management Process - Part 1 - to be continued)

Strategic cost management process

The comprehensive product cost management process starts when the needs of the customer group are transferred to the features of the offer. The review period of the planned product is the entire life cycle from the birth of the product to the scrapping of the product at the end of its useful life. Focusing on the entire product life cycle is a basic requirement for comprehensive product cost management.

The second dimension is the examination of the entire value chain of the product, which means the company's internal costs and external costs.

Cost control techniques are used to systematically reduce the costs of the planned product. These techniques include the following cost management processes:

New product cost management

· Target costing process (Target Costing)

· Cost planning (Value Engineering)

· Interorganizational Cost Management

Cost management of existing products

· Systems based on continuous systematic improvement (Kaizen Costing)

· Value analysis (Value Analysis) and cost planning (VE)

Such a cost management entity is called a Strategic Cost Management Process , because it is a continuum of several, well-known, problem-solving methods.

The design of new products begins by finding out the customer's needs for the product being designed and ranking them in order of importance. In general, in industry, customer requirements become equal and eventually the designer finds himself in conflicting choice situations and eventually the costs of the product get out of hand. The product itself can turn out to be very high-quality, but only a few customers are willing to pay for low-value features, in which case the product's profitability can remain modest.

In the strategic cost management process , by new product I mean a product that has already been manufactured, but it is no longer competitive, e.g. in terms of price, and therefore needs to be redesigned.

After the process of prioritizing customer needs, the designers' task is to determine which functions of the designed product correspond to which customer requirement. These functions are the design engineer's solutions to implement the customer's requirements.

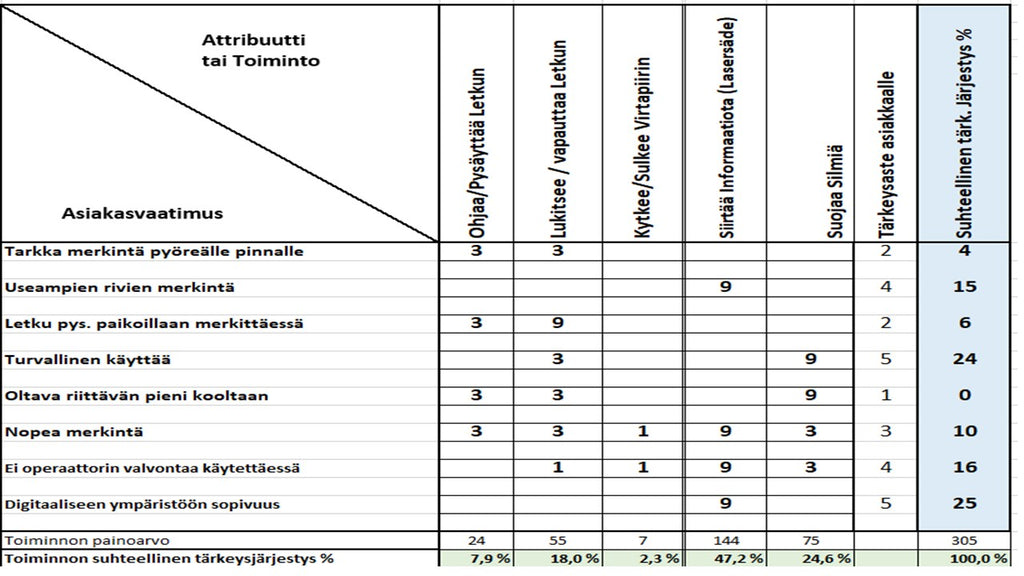

Each component that is later designed into the product represents functions related to the product, therefore the customer requirements must be related to the functions that best represent the customer requirement under consideration. This rationing takes place with a coefficient, which describes the strength of the correlation between the component/function and the customer requirement (example figure 1).

Figure 1. Relative order of importance of functions and customer requirements

As mentioned above, the customer requirements are changed into the order of importance of the components/functions. This is important because customers think of a product in terms of its features, but products are designed in terms of functions and components. To analyze this interaction, the percentage impact of each component/function on customer requirements is determined and finally the relative importance of the components/functions is determined.

In this way, two important ratios have been defined; Relative order of importance of customer requirements , which indicates the weight given by the customer to each customer requirement. The second is the relative order of importance of the components/functions contained in the product to customer requirements.

Since the target cost concept always starts from the costs of the existing product and its parts, which are the starting point for the design of the new product, this information can be used in calculating the value index . This index determines the relative importance of the component under review in relation to the relative cost of the component. It is also called the degree of importance for the customer, because it shows whether the customer value of the component set by the customer is correct in relation to the weight the customer has set for it. The aim of the index is number 1, a number below one means that the the costs of the component must be reduced without reducing its customer value or quality level. If, on the other hand, the number is more than one, then the customer value of the component must be improved, because too few costs have been allocated to it in relation to the customer's appreciation of the component.

The cost balance of the entire product can be found by calculating the customer value of all components separately. Components deviating from value 1 are subject to Value Engineering analysis.

Value Engineering is a tool to solve problems like the one above. Its goal is to produce functions that the customer needs at the lowest possible cost level, without compromising the quality or functionality of the product.

Pentti Enlund

Target Costing and Value Engineering Expert

Mexlink Oy

English

English Finnish

Finnish Swedish

Swedish German

German

D Change On

Please let me know if you’re looking for a author for your

blog. You have some really good posts and I feel

I would be a good asset. If you ever want to take some of

the load off, I’d love to write some content for your blog in exchange for a link back to mine.

Please blast me an e-mail if interested. Cheers!