ÄVE (Smart Manufacturing in the Ecosystem) From a research forum to industrial applications

Posted by PASI JULKUNEN

The ÄVE project has ended with amazing results in terms of the share between the research community and the companies. A few business projects will continue until the end of the year due to delays caused by Corona.

In the Smart Manufacturing Network, during the project, the research gradually accelerated to bring the know-how of the opening manufacturing industry to a fading state. A period of two years is a short period of time for research, but the ÄVE project was able to create a few significant renewal leaps for application and many level raises, which will already allow us to show new potential paths of ability to industry in the future.

Kari Koskinen sheds light on the entire course of the project, from starting point to result: ave final seminar introduction pdf

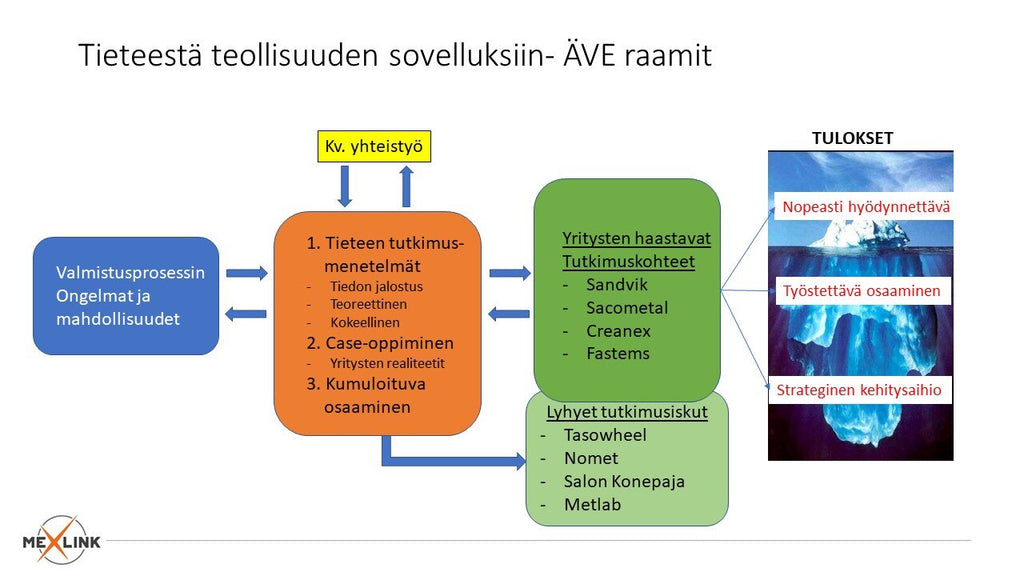

A very significant aspect was the genuine cooperation between the University of Tampere, TAMK and VTT. About 40 researchers participated in the study with different contributions. Here, departmental boundaries were crossed and budgets were transferred within the units on the same principle. The research groups showed commitment to goals and a culture of achievement. Attached is a model by which information was processed for the short and long term - Science's path to industrial applications from Pasi Julkunen's presentation: the role of research knowledge in building a competitive advantage in the engineering industry pdf

Research data refinement process as a co-development concept

The modification of grinding know-how from tacit knowledge to artificial intelligence applications was a significant increase in know-how, which brought back grinding know-how to Finland. In addition to mechanical engineering and materials science researchers from Tampere University, RWTH Aachen's grinding research group, Sandvik as a platform for tacit knowledge and experimental activity, and Creanex, from which we expect a unique digital twin of the grinding process in the near future, collaborated. Arttu Heininen's presentation on the research: components of the digital twin pdf

Artu's presentation also describes the emergence of research environments in TAMK and TAU infrastructure. Grinding research equipment (TAU) and FieldLab (TAMK). The need for grinding skills will increase due to climate change pressures, because durability has a significant impact on both logistics emissions and material use. Currently, the educational expertise is only held by MexLink and networked with Aachen University. In the Konepajakoulu 2.0 pilot projects, we will start putting lost skills on the map of education.

Another one that moved in the footsteps of a disappearing folk tradition was the project of transferring the silent knowledge of demanding mechanization into the visible. Nillo Adlin, who did the fieldwork, showed the Finnish strength, where a doctor-level guy puts on overalls and comes to the machine shop for morning and evening shifts to live for weeks in the realities of the machine shop. However, Nillo was not satisfied with just watching, but approached the matter with Fujimoto's method and involved master-level machinists to develop a common vision.

The path of the tacit knowledge of mechanization towards the ability to internalize

Two methods, the know-how of which is slowly disappearing along with the retiring Masters, were able to be put back on the path of development. Demanding machining is also slowly disappearing as a skill type as master level machinists retire. The steps of machining know-how will also be used in setting up the Konepajakoulu 2.0 concept.

Mechanical engineering school 2.0 concept

In the field of materials science, we went to the top of the world, where the road continues and the gained understanding can already be put into products. Attention to the variation in raw material quality between different melting batches and delivery batches is a significant increase in understanding for both product developers and quality management. A simulation-based approach, on the other hand, makes it possible to search for the desired properties in a modeled operating environment. This is the joint view of Pasi Peura (TAU) and Tomi Suhonen (VTT): materials pdf

The path of materials expertise to the forefront of industry

At the same time, the world's largest cyclic fatigue device was created, with which various heat treatments and manufacturing parameters can be verified in terms of durability effects. In the third package, a career was opened for the industry's real-time verification of the stress state of a piece as a combination of a measuring device based on the Barkhausen method and artificial intelligence. From these fruits of material research, we can expect solutions for both sustainable development and enabling the reliability base of new digital product layers.

Costs and creating value in a financial sense tend to be forgotten in the technology frenzy, so Jari Paranko puts his feet firmly on the ground this time in the challenges of SMEs, i.e. the change in the customers' procurement process towards a more project-like operation. In the initial phase, more cost structures were mapped and traces of them led to the procurement interface: influencing profitability from the perspective of strategic procurement pdf

I recommend reading the entire final report, because there you can find information relevant to your needs: ave results report 2020 pdf

The scientific community also needs a continuum of companies to further refine these results. I hope that this good work spawns new projects where it is worth using the lessons learned from cooperation in the style that Kari Koskinen launched: Let's do more together.

English

English Finnish

Finnish Swedish

Swedish German

German

Teknik Informatika On

How did the ÄVE project manage to achieve significant renewal leaps and raise industry standards within the short two-year timeframe of the Smart Manufacturing Network, and what potential paths for future industry development have emerged from these advancements?

Regard Telkom University