Find out about the machine shop's new product

Posted by PASI JULKUNEN

The manufacturing industry is at a crossroads where the future of the company should actually be decided. Digitization is certainly on everyone's agenda. How should it be handled? When and how to jump on board? Wrong choices can collapse the company's profitability in the long run. On the other hand, not making choices leads to the same problem after a while. Information as a product is foreign to Rautakour. It cannot be machined or welded. However, information in the production process is central and so everyday that its value in future business is difficult to perceive. However, information from the production process must be processed in a new way in order to turn it into a profitable business.

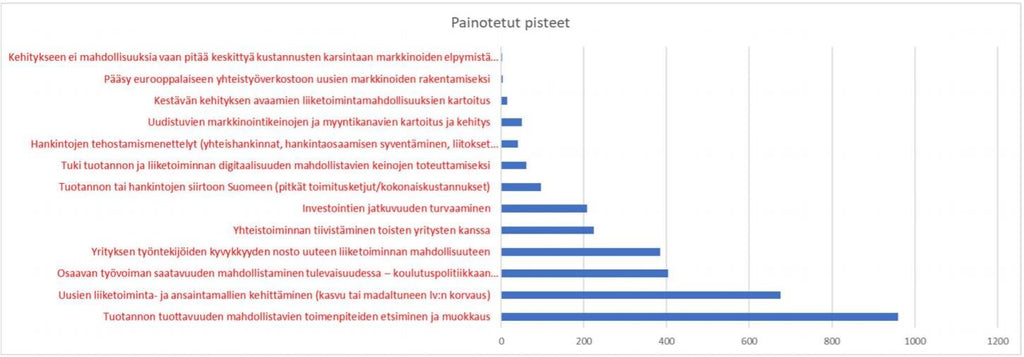

Information must produce value profitably. Business Tampere conducted a study in which MexLink produced an SME industry view of business priorities in the strangling grip of Corona. The priorities that the company management brought up:

The three most important emphases came from production productivity, new business models and know-how, i.e. precisely those for which digitalization opens up possibilities when properly dosed. Digitization as a concept has suffered erosion, when the lack of understanding of business and technology has made it a buzzword.

The well-known connection between digitization and productivity is business transparency, i.e. anticipation, which optimizes material flows. Another deeper effect comes from the product properties themselves by affecting the manufacturing process. There are technical tools, but they must be synchronized through the construction of many key cooperation bridges. However, the definition of IT technology suitable for the target may become an obstacle if the interface cooperation of SW-based companies is not controlled.

If you don't know how to renew business models, change trends will easily drive passively waiting companies in the processing chain to lower levels of tighter margins. Utilizing digitization requires cooperation between companies. Supplying companies have to find the core of customer needs and the current transaction-based contacts are not enough. Buying companies have to come from behind the contract papers to understand the dynamics of the supply chain and the basics of productivity, which are typically influenced by their own requirements.

I will write more in the next article about what is happening in the world around this issue and how to build change, and it is also worth taking a look at our offer.

18.7.2020 Pasi Julkunen

English

English Finnish

Finnish Swedish

Swedish German

German

D Change On

Hi to every , since I am genuinely eager of reading this website’s

post to be updated regularly. It carries good material.

D Change On

Pretty! This was an extremely wonderful post.

Thank you for supplying these details.

D Change On

Someone essentially help to make significantly articles I would state.

This is the very first time I frequented your website page

and so far? I surprised with the analysis you made to create this particular put

up extraordinary. Great process!

D Change On

If you would like to grow your experience just keep visiting this site and be updated with the hottest

information posted here.

d-change.net On

Do you have a spam problem on this site; I also am a blogger, and I was curious about your situation; many of us have

created some nice practices and we are looking to exchange techniques with other folks, please shoot me an e-mail if interested.