Manufacturing development trends in Germany – what can we learn?

Posted by PASI JULKUNEN

Surely everyone is familiar with one of the strongest manufacturing trends - Industry 4.0, but what is behind it and what else is coming. Industrial cultures give their spice to each step of development. This article looks at Germany because it can be considered a leading country in the manufacturing industry. On the other hand, Industry 4.0 was born from the weak penetration of digitalization in the German manufacturing industry, to which a strategic change was sought: "strong ability to customize products under the conditions of flexible mass production".

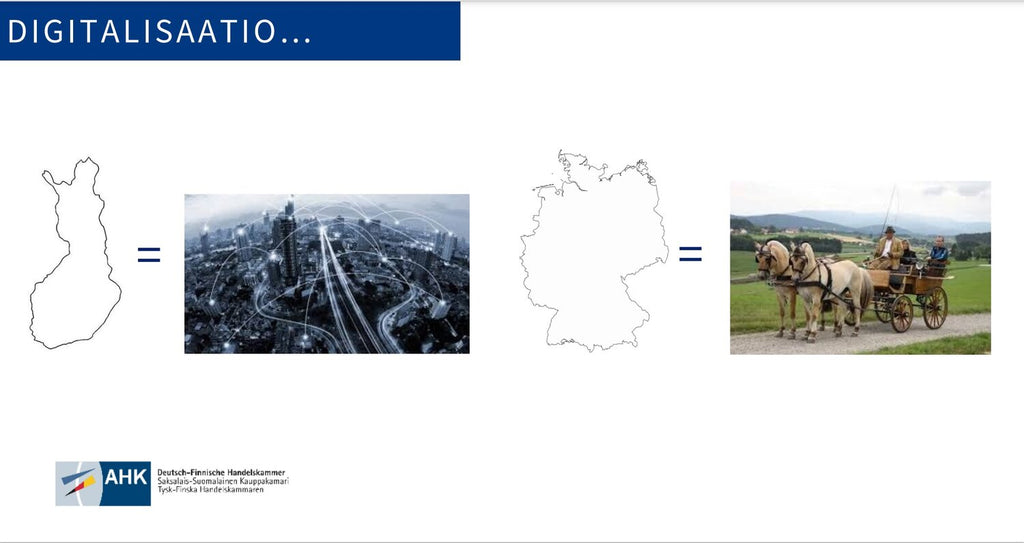

Director of the German-Finnish Chamber of Commerce, Jan Feller, describes the basic situation of digitalization in Finland and Germany at a general level in figure 1.

Figure 1. Feller's description of the nature of the digitization platform in Finland and Germany (Business Finland's Smart Factory – Germany seminar 15.6 2020, https://www.businessfinland.fi/49dc0b/globalassets/finnish-customers/02-build-your-network/bioeconomy-- cleantech/sustainable-manufacturer/jan-feller-ahksmartmanufacturingahk.pdf )

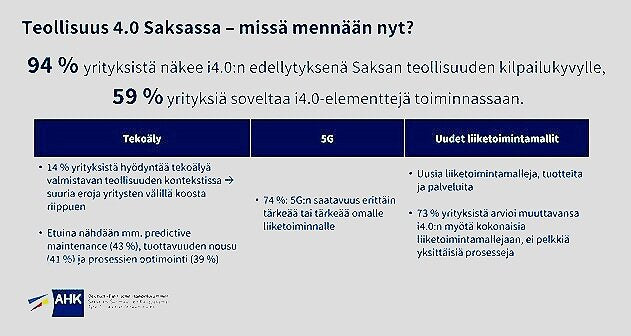

The implementation of Industry 4.0 has been approached strategically and it cuts through the entire German research world as well as the business world, and the pace is accelerating all the time. Industry, on the other hand, is progressing more slowly, but the will to change is strong despite the shortcomings of digitization structures (Figure 2). For example, in operations between companies, the connection of information flows is weak, even though the elements of digitalization have awakened within the own factory. In Finnish industry, on the other hand, similar structures are even self-evident, but the ability to turn them into superior factors for business is lacking. One difference is also trust. In Germany, even the order confirmation is given in the form of a letter with the terms of the order on the back. This has been tried to ensure that the customer will certainly pay for his order. These practices still run deep, even though some of the industry has changed.

Figure 2. Feller / Business Finland 15.6.2020: The will of German industry

However, German manufacturing know -how relies heavily on knowing and deepening the basics. They are seen as a prerequisite for utilizing digitization. Similarly, the research relies heavily on, for example, understanding the event between the piece, the material and the machine, which would also seem to support the rising trend of sustainable development. Manufacturing's support for research is strong, and the renewal of companies draws strength from this interaction.

When looking at German industrial locomotives , the automotive industry is an undeniable pioneer and influencer. When profitability is tight, the processes of the automotive industry are known to be tuned to the extreme, but to serve volume manufacturing. Although in Germany there is talk of a trend towards more agile and even one-track flow, the culture slows down real changes. The electrification of car power lines is shaking the traditional metal industry violently and leads to new kinds of needs, where the characteristics of the final products require much more than conformity to the drawing. For example, copying of spare parts and product liability require protections, which emphasize e.g. individual tracking of parts.

The world of research , to which German industry is strongly attached, shows the way to the future and with German-style straightforwardness. The industry is very engineer-driven and academic values are deeply respected. To detect trends, let's look at the strong manufacturing research center WerkZeugmachinenLabor WZL der RWTH and Fraunhofer IPT Aachen, both of which are led by WZL's processor quad ( https://www.wzl.rwth-aachen.de/cms/WZL/Das-WZL/Profil/~ceexv /Ueber-uns/lidx/1/ ). The research areas tell the direction of German industry: a strong contribution to basic skills cutting machining, grinding, monitoring of production processes and production technology in general. In addition, a special focus is on gear manufacturing, and digitalization can be found under the title "Digital Transformation" under the title of production technology. 5G Industry Campus Europe ( https://5g-industry-campus.com ) has been established in Aachen, which rises to the crest of the Industry 4.0 wave. This also shows the strong emphasis on volume thinking, i.e. the efficient processes of the own factory. Different universities have different emphases, but the common "DNA" is Industry 4.0.

What conclusion should we draw when the national infrastructure and the culture of small manufacturing batches create a stepping stone for us in the future? In larger locomotive companies, the transformation has already started, so examples are starting to emerge. Perhaps the Germans will teach us the meaning of putting effort from the center of the basics. If you don't know the ways of doing things and related processes, how can you produce food for digitization, i.e. algorithms (an example of the role of algorithms https://www.linkedin.com/pulse/algoritomiosaamista-syntyy-kun-matemaatikot-ja-timo-hakkarainen ).

Finnish industry, and especially SME industry, is in a hurry to invest in connectivity, information processing and learn by piloting how technology initiates new business operations. You also have to take risks and wake up customers in a new way with alternative earning logics. The German market is now in demand for capable machine shops as manufacturing is brought back from cheap countries.

Finnish manufacturing training and research has a place in the fight, because it has been pushed into a corner by pure digitalization hype displacing the basics. Would it be possible to cultivate both thinking here? Let's take advantage of the strong degree of application of digitalization and revive the basics, from which springs the growth of digitalization! The marginal conditions of financing must also be thought through strategically based on the real need for renewal and taking into account the starting level, using the example given by the German government. Where there is a lack of competence, it requires both humility to admit it and alliance with top experts, remembering that we also have quite a bit to give in the digitization sector.

Pasi Julkunen / 17 August 2020

English

English Finnish

Finnish Swedish

Swedish German

German