Solutions for the critical shortage of CNC Machining operators

Julkaisi PASI JULKUNEN /

There is a lack of industrial professionals nearly in every European country, especially on the factory floor. In Finland, we also are experiencing the same trend. For example, in the Tampere region, which is the center of metal and machinery industry in Finland, about 200 CNC Machinists will step out of work markets while only about sixty-five new graduates from the region’s vocational schools. Some of this gap can be alleviated by importing workers from the other regions but there is a fierce competition of talent. This could mean a survival game between companies that can lead small companies into bankruptcy releasing some labor for markets.

Small size often means agility as a network member in supply chains for their large international clients. However, it requires different kind of orchestration than businesses where big companies control large amount of manufacturing value inhouse and perhaps purchases part systems from own subsidiaries. However, to be too small means that resources on education interface are too lean.

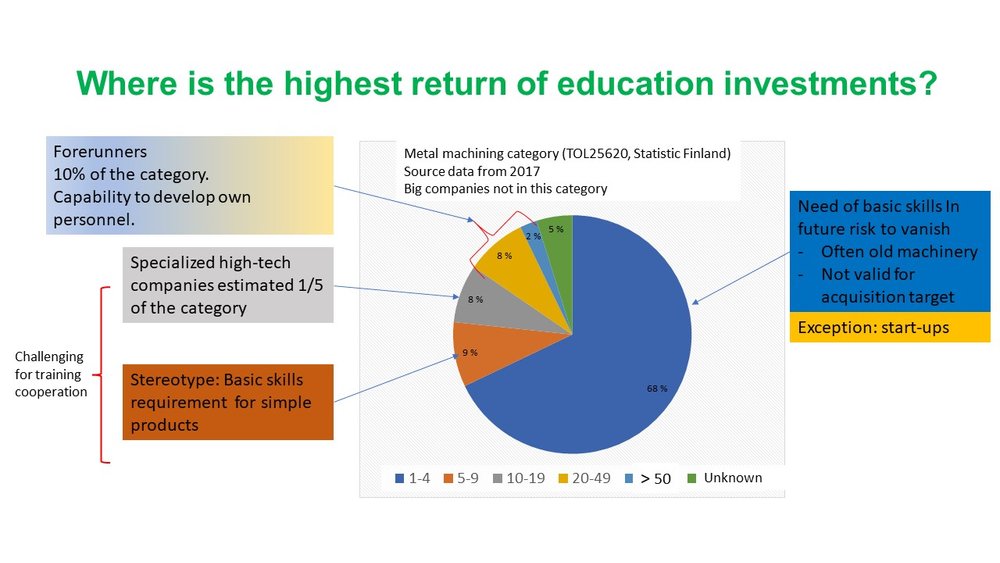

Picture 1. Metal machining industry (SMEs) in Finland by personnel

The key question is why this happens? Is it due to politicians focusing on a higher-level education and not fully understanding the role of digitalization in the manufacturing industry? Is the national education policy focused more on saving money and thus outsourcing teaching to students? Are industry players not investing in training and the image of the manufacturing industry? Are salaries not attractive enough? Do industry managers not understand the importance of the critical role of competence in enhancing productivity?

All these questions drive establishing strategies to find solutions:

Creating appealing professions and a clear future professional track for then young generation – time horizon 3 years to graduation + 3 years to productivity in industry

Importing experienced professionals – considering language, industrial culture, and the high European competition – time horizon 0-3 years to productivity

Focusing on the biggest group (those who are currently working in the field) – productivity leap to compensate the poor availability of professionals – time horizon months

The last option above is the fastest one but will require simultaneously investing both in the system layers and automation. Developing competence of existing professionals could create an impact quicker in 3-6 months considering that the delivery time of a modern machinery is currently 12-13 months. Competence and investment driven actions are much faster than starting education from zero, however without neglecting the importance of a need for a longer-term solution. In picture 2 the flow of different sources of professionals is balanced and on critical element is to influence productivity.

Picture 2. Employee sources and education potential in Tampere region

The source data from the Statistic Finland might not have exact validity but provide an overall picture. Anyway, a more straightforward action is to either acquire competent labor abroad and then to train them, or to seek a higher impact by focusing on the majority who are already active in the labor market. It is obvious that cell automation and system level tools are needed to achieve the goal - maybe system focus first and then automation. However, our conclusions on competence mapping and practices in high-tech companies are supporting the fact that the digitalization of manufacturing is supported mostly by basic tacit skills. This skillset might be wider than the current scope of traditional CNC Machinists. Digitalization around the CNC Machinist does not mean extra digital skills. CNC = Computerized Numerical Control origin is from 1950’s and using high-tech machinery is not anymore reason to glow digitalization. It is more system and method design level issue. If companies start to measure OEE or TEEP, then operator’s competence will become visible. How to manage exceptions (tooling, setup/changes, unplanned maintenance, speedlosses, material shortage, order fluctuation, material shortage, sick days, …). OEE could ealily drop to 50-60 % of available hours due to exception management especially in non-robotic cell. In wider cell automation concept, there are potential in the cell team of operators to adapt to changes. However, sick leaves are hard to adapt, because there are no professionals waiting at the company’s gate ready to jump to operate a new machine.

Picture 3. Separation of system (digital) company level capability and applying machining competence

How to turn the shrinking trend to growth by actions?

The first activity as to link companies and education tighter together. For example, this was done by the Engineering Academy 2.0 project in 2020-2021: Systemizing cooperation of companies and education (https://konepajakoulu.fi/en/). We also can find a world class example from Germany, where a Dual Education concept is organized aligning with the structures of society: https://m.youtube.com/watch?time_continue=1&v=sXhSRoSFxuU&feature=emb_title

However, this German model has weaknesses since 75 % of education will take place in companies. The education technology and modern tools could be university and Fraunhofer-based, but this approach is theoretical with high-level research towards a vocational education. Tacit knowledge will with a higher probability remain in the mind of the working people. The other cultural barrier is a traditional systematic way with hierarchies. In Finland, the government actions have been focusing purely on the higher education, and the theoretical level has decreased to a dangerous level in the manufacturing science. However, tacit knowledge is still built into industry players’ personnel and system level. We can learn a lot from the German system, but our industry infrastructure is different. We need to build this inside out first.

We at MexLink created a competence map by a firsthand approach on production line collecting tacit knowledge from experienced and non-experienced people. It is important to respect views of those who are not in a high level in the organization and can provide important information directly to achieve a high level of worker competence. MexLink followed this approach first with one Finnish company as our service offering. We succeeded well in this project and cooperated with the Engineering Academy how to evaluate the concept with two different companies. Our approach there was to take a master level and a medium level CNC Machinist to evaluate the prototype of the competence map we developed during this process. We next asked top-class experts from different areas of to provide us feedback. To develop a future concept, we benchmarked a high-tech company in Sweden to gain a world-class understanding of the role of automation and digitalization related to the competence elements. Finally, after modifying the technical language to “learning language,” the final competence map was built (Picture 4):

Picture 4. Finalized MexLink competence map of CNC Machinist in manufacturing industry (221 skill elements)

Instead of jumping to a digital jungle, we made WxH 130 cm x 110 cm large table on a magnetic platform. This provided us better a big picture than our Excel-prototype with high-level links to relevant support materials. For a human being, this kind of boardgame is supporting thinking and critical self-reflection. An industrial designer provided the visual layout with his professional eye and made the boardgame easy to approach. In the competence evaluation, there will be at least the person who is making the self-evaluation, an advanced peer machinist or a manager. So, team thinking as well as evaluation will be supported better by this big boardgame approach.

Digital interface to the competence map

We need to extend the analog competence map to talent management and mass customization of training sessions. Then we need a digital platform to collect, analyze and share data for different use cases (Picture 5).

Picture 5. Digital extension of the MexLink competence map

A company needs to understand the level of competence of its own personnel and connect it to talent management strategies, identify risks and potential new business cases. Competence development is an annual layer-by-layer development with new extension of skillsets. Following up such a development requires a systematic connection to history and future. Training providers need to get statistics about the specific needs to be able to design the right offering for a specific target group in different companies.

Training technology as a tool and an attraction

While digitalization in the manufacturing industry can lead to sometimes unrealistic expectations, there is one appealing domain that is very strong in Finland: Artificial Intelligence (AI)-based education as a form of learning analytics and simulator-based training. Manufacturing of forest machines was one of the first adopters of simulator-based training, and rock drilling rigs were the second pioneers to react the same phenomenon as fabrication industry now – shortage of operators (https://creanex.fi/en/training-environments-for-schools/).

Both industries reacted the shrinking interest to get operators to support the customer industry. We applied the same concept to grinding and developed together with Creanex, Tampere University and RWTH Aachen (Germany) first a virtual grinding cell simulator. MexLink contacted the Eduten and the Turku University to evaluate the world class technology possibilities for industrial applications. Therefore, we have now the technology and competence to apply the driller training idea to manufacturing industry. We only have a final task remaining: to get funding to make training modules and to connect AI to support learning. I bet this kind of method will wake up an interest to a more modern manufacturing industry (picture 6).

Picture 6. Simulator-based training – case grinding

This is not anymore, a vision, it is a doable reality. A novel dimension is Learning Analytics that is one of spearheads that builds on strong Finnish education platforms and knowledge. Algorithms of Learning Analytics are based on learning theories and human behavior. It needs just additional work to apply two known technologies to a new domain.

Potential career paths to CNC Machinist newcomers

The image of metal and manufacturing industry has lost attention to the digitalization trend, even though it is applying real digitalization and automation in manufacturing. Therefore, to wake up the interest needs future vision to attract new workforce in the field. Newcomers have questions such as: How would my future look like in the industry? What kind of opportunities I could have to grow if my capabilities are strong enough to jump to the next level? Here is on scenario map for CNC Machinist (picture 7) that we at Mexlink have developed for further consideration in industry.

Picture 7. Scenarios to grow in lifetime perspective by developing continuously own competence in the Finnish scope (different paths possible in different cultures)

Summary

The competence map of a CNC Machinist is not only a map. It is a platform that will open several paths for several stakeholders. In this article, my focus is to open the idea of the competence map as a part of practical talent management in the manufacturing industry, as well as to provide tools for education partners. The final goal is to offer solution for shortage of professionals. I would like to welcome companies and training providers to speed up the progress to ensure productivity and availability of skilled work force for the manufacturing industry.

The set of magnetic tables with some options will be soon available from MexLink, but you can ask quotation before our logistic processes are finetuned for faster delivery time.

25.10.2022 (updated 23.8.2023)

Pasi Julkunen

CEO

MexLink Oy

Suomi

Suomi Englanti

Englanti Ruotsi

Ruotsi Saksa

Saksa

d-change.net

Hmm is anyone else having problems with the images on this blog loading?

I’m trying to find out if its a problem on my end or if it’s the blog.

Any responses would be greatly appreciated.

D Change

Attractive section of content. I just stumbled upon your

web site and in accession capital to assert that I get actually enjoyed

account your blog posts. Anyway I will be subscribing to your augment and even I achievement you access consistently fast.

D Change

magnificent submit, very informative. I ponder why the other specialists of this sector

don’t notice this. You should continue your writing.

I’m confident, you have a great readers’ base already!